TRD

Supercharger Kit

Contents:

Introduction:

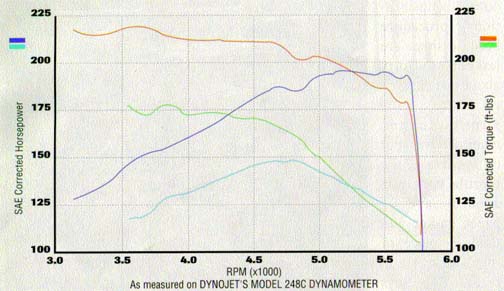

This dyno chart was

scanned out of Today's SUV Magazine. It shows the before

and

after supercharger dyno runs. This chart shows an increase of

40 peak HP and a

max increase of near 60 HP.

There is

no other performance modification that comes close to

the fun that the TRD Supercharger can give you. Most

other mods might give you some added performance in

one area while decreasing it in another. The

supercharger increases performance in all areas, low,

midrange, and top end.

Most people and I report

loosing only 1 MPG after installing the supercharger.

That is a wonderful trade off for the added fun you

will get from installing it, not to mention the cool factor.

Back

to page index

How

a supercharger works and different types:

The engine draws into the

cylinders when the pistons are moving downward in the

cylinders. This creates a pressure in the cylinders that is

less then the air outside the engine. The air outside the

engine tries real hard to move into the area of negative pressure in

the cylinder. What this means is that air is not sucked into

an engine but forced in by the higher air pressure outside the

engine.

The amount of air the engine

can consume, mix with fuel, and burn determines the how much power

the engine can make. Usually, engines of greater displacement

can consume more air and fuel and make more power.

The down side to this is

that engines of greater displacement have larger internal friction

surfaces inside and that robs power. In cruise a car requires very

little power to maintain speed on level ground. Lets say a car

needs 18 HP to maintain 60 MPH. Now if you use a very small

engine to make that 18 HP it will be more efficient due to less

internal friction then a very large engine making 18 HP. This

is the biggest reason that smaller engines get better MPG then larger

engines in cruise. The problem is there are times that you

need much more power like merging into traffic on the interstate.

This is where a bigger engine comes in handy, but you pay a fuel

penalty when that larger engine is not needed.

There are advantages to

making a smaller engine more powerful. That way they can make

the power needed, and still get better fuel economy. One way

to do this that is getting more popular is to force more air into

the engine then it would normally draw in on its own. This can

be done with some kind of forced induction. The most common

ways to do this is with a turbocharger or supercharger.

A turbocharger has a turbine

that is driven by spent exhaust gasses and that in turn spins a

compressor wheel. The compressor wheel causes more air to

enter the engine then it would normally draw in on its own thereby

increasing power. The advantage to an exhaust driven turbo is

that it is more efficient then an engine driven compressor AKA

supercharger. A piston engine is said at best to be only 33% efficient.

1/3 of the energy released from the burning gas is converted to heat

that goes into the engine's cooling system. 1/3 of the energy

powers the car. 1/3 of the energy goes out the exhaust pipe as

heat. The turbocharger harnesses some of that 1/3 wasted

energy that goes out the exhaust to increase the power of the

engine.

There are lots of other

things that are really nice about turbochargers, but in an

aftermarket bolt on application they can be very complex to install

as it involves lots of plumbing changes in the exhaust, air

induction system, oil system, and so on. This is where the

supercharger has some advantages. It is an air pump that is

driven by a belt from the crankshaft and no mods to the exhaust

system are needed. Overall the biggest advantage is it utter

simplicity even if they are less efficient then a turbocharger.

Another advantage is the impellers are always turning at the ideal

speed to provide full boost as soon as the throttle is opened.

In a turbo you have to wait for the turbo to speed or spool up to

provide the boost. That is called turbo lag. That does

not happen with the engine driven supercharger, you get boost as

soon as you crack the throttle.

Centrifugal

and Positive Displacement Superchargers

There are two basic types of

superchargers, positive displacement and centrifugal.

The centrifugal

superchargers use the same type of compressor impeller as a

turbocharger and the faster they spin the more boost they make and

it is not linier. If you double the speed of the compressor

you quadruple the output. The problem is that they only make peak boost at the

engine's redline and tend to make very little boost at lower engine

speeds where they are mostly operated. These are the type used

by the well known Paxton and Vortech

brand. In automotive use they really

are not the best choice because of the very wide RPM ranges used in

normal operation. They are very well suited for aircraft use

where the engines are operated in a very narrow RPM range the entire

time the aircraft is in flight. There are many auto

manufactures that are using positive displacement superchargers on their

cars, Mercedes, Jaguar, Ford, GM, Saab and many more. Not a

single one that I know of is using a centrifugal supercharger.

There must be a real good reason for that.

The positive displacement

supercharger will move a fixed amount of air on each rotation and

that is not dependant on impeller speed as it is on the centrifugal

type. When a positive displacement supercharger's size is

properly matched to an engine and it turned at fixed ratio to engine

speed it will produce a set amount of boost throughout almost the

entire RPM band, from just off idle to full RPM. There are

great advantages to this over the centrifugal type superchargers and

that is why they are the better choice.

Types

of positive displacement superchargers-

Reciprocating-

This is the common piston in

cylinder type. These are mostly used as air compressors and

not to many are used as superchargers as they are not any more efficient

as the piston engine its self.

Vane-

These use a central shaft

with sliding vanes inside a housing of decreasing radius. They

have been used on older cars of the past. The most current use

of this type that I know of was the VW G-Lader. This also very

similar to most power steering pumps.

Wankel-

That's right the Wankle

engine started out as a supercharger before someone got the idea to

install spark plugs and shooting in gas and call it an engine.

Lysholm-

Lysholm superchargers are similar

to the modified roots type, but the impellers are dissimilar.

One is a male rotor of three or four lobes and the other is a female rotor

of five lobes. The Lyshlom superchargers are used more in

applications where the boost pressure is over 13 PSI.

The reason for this is that the supercharger compresses the air to a

high degree inside the supercharger and it decompresses as it enters

the plenum. The advantage to this is that the air in the

plenum will not back flow into the supercharger as the pressure in

the supercharger is always more then in the plenum. The side

affect to this is higher heat and more parasitic drag then the

modified roots type in non and low boost conditions.

Saab and Mercedes Benz uses

the Lysholm superchargers, but Mercedes only uses them only in their

high boost applications and the Eaton modified roots type in their

low boost applications. Currently Mercedes is using Japanese

made Lysholm superchargers and has asked Eaton to supply them for

their high boost applications. Eaton has obtained the license

from the patent holders to start producing Lysholm superchargers for

Mercedes.

There are some aftermarket

companies that use the Lysholm supercharger in their kits.

Some of them are Stillen and Kenne Bell. They are sometimes

referred to as screw chargers.

Roots and Modified Roots

Type-

The roots is the oldest type of positive

displacement supercharger. They started out life made of wood

and were used to ventilate mines and as blowers in blast furnaces.

This is the type you see sitting on top of those big top fuel

dragsters. In these the air comes in one side and travels

around toward the outside of the housing and as the impellers mesh

the air is forced out the other side. The most common use of

this type supercharger or blower is on the Detroit two stroke diesel

engines. They are needed to force air into the intake ports on

the two stroke diesel engines and they would not run without

them. This is the type of engine that is used in most of the

fire trucks and buses. It is not known as the most efficient

type of supercharger. The later Detroit two stroke engines had

both a blower to make them run and a turbo for top end power. This

was done in the Silver series until the Feds banned them for

emission reasons. You now will only find new ones in marine

applications.

This

is what the impellers look like inside the TRD Supercharger. Notice

the twist of the impellers.

That is modification that Eaton came up with to make them more efficient.

This

is a picture from the intake end of the impellers.

To make the Roots type

more efficient, Eaton has modified the impellers by adding a twist

to them and moving the intake port to the end. This makes them

more efficient and quieter. This is called a "Modified

Roots" type supercharger. This is the type used in the

TRD Supercharger kit. The biggest difference between the

modified roots type and the Lysholm supercharger is that the

modified roots type has two impellers that are same, where the

Lysholm uses two dissimilar ones, a male and a female rotor.

This

is the supercharger housing. The intake port is the big hole on the

bottom in the rear.

Air is draw in there to fill the empty space between the impellers

and then carried out toward the outside

and toward the top. When the impeller lobes intermesh at the

top the air is forced out of the space

between the lobes and out the discharge port on the top. You

can see the little holes on each side of the

discharge port. Those are placed there to increase the

discharge efficiency and is called "S" porting. That

is

fairly new thing.

The modified roots type is

the best type of supercharger to use until the boost pressure

exceeds 13 PSI. At that point the pressure in the manifold

starts to exceed the pressure in the supercharger housing and it

starts to backflow into the supercharger and decreases its output

and the heat generated really goes up. Above 13 PSI the better

supercharger would be the Lysholm type. It is said that the

compression of the air occurs in the plenum after it leaves the

supercharger in the modified roots type supercharger unlike the

Lysholm where the air is compressed inside the blower and then

decompresses as it leaves the blower and enters the plenum.

The advantage with the modified roots type is that it has less

parasitic drag on the engine when boost is not needed. The

Eaton superchargers also use a bypass valve that equalizes the

pressure on both sides of the impellers when the engine is operating

in vacuum. This takes more load off the engine and reduces the

heat generated in non-boost conditions. The Lysholm is still

compressing air internally even during non-boost conditions and this

generates heat and has more parasitic drag on the engine during

non-boost even with a bypass valve. Mercedes Benz does use some

Lysholm superchargers

on their super cars and they employ a clutch to disengage the

supercharger from the crank shaft during non-boost conditions to

counter the negatives of the Lysholm superchargers.

Overall the modified roots

type supercharger is the much better choice if you are staying under

13 PSI of boost. This is why most of the OEM producers choose

the Eaton modified roots type superchargers for their production

cars.

The Eaton modified roots

type supercharger is the one that is best suited for the Toyota 3.4

supercharger kit given its low boost, low parasitic loss during

non-boost conditions, and instant full boost throughout most of the

RPM band.

Back

to page index

The TRD Supercharger kit:

The kit is produced by

Magnuson Products for TRD. They also make kits for other

companies like Jackson Racing and

Neuspeed, and help develop supercharger

applications for many of the OE manufacturers, like GM. The original supercharger kit which

is the one that I have uses an Eaton M-62 3rd Generation

supercharger. It has a 62 cubic inch displacement. The

first design kits had a separate plenum that the supercharger was

bolted to. The plenum is the part that carries air to the

engine that is higher then atmospheric pressure also know as boost

pressure. It also doubles as the mounting for the

supercharger.

The newer or current

supercharger kit uses a single casting for the supercharger housing

and plenum. It is based on the newer 4th generation Eaton

supercharger. It differs from the 3rd generation mostly in

respect to the bypass valve. In the 4th generation the

supercharger body has the bypass valve cast into the supercharger

body where on the 3rd generation it was a separate part that had to

be plumbed into the works some how. This saves space and

allows a more compact installation so it can be fitted to more

applications. Magnuson has taken this to the extreme and made

the supercharger body, bypass valve, and plenum all one casting to

make for a very compact installation. Some people get confused

thinking that the new supercharger is a totally different

supercharger. It really is not. It is still an Eaton

M-62, 62 cubic inch supercharger. Magnuson has really done a

fantastic job on the second version. The layout and casting is

very well thought out and still uses all the factory connections and

cables. The newer one is easier to install saving on

installation time and confusion.

You can download a

compressed file containing several pictures of the 2nd Generation

TRD Supercharger Kit by clicking here.

You can see how Magnuson cast the housing, plenum, and bypass valve

all as one compact unit. It is very nicely done.

Back

to page index

Installation:

The supercharger replaces

the upper and lower intake connectors and bolts to the

manifold. The upper intake connectors are the long aluminum

tube looking things that are between the throttle body and the

intake manifold. The kit retains the stock throttle body and

all the vacuum hose connections. If you have an EGR system on

your truck there is a provision for this, but you will have to

purchase an EGR adaptor kit at extra cost.

The installation is fairly

simple and requires unbolting and removing the intake connectors,

installing a longer alternator belt that will now also power the supercharger and

reconnecting all the vacuum hoses. The hardest part of all is

removing the A/C compressor and power steering belt to get to the

alternator belt. This is not hard to do, but is

tedious. If you can replace your

belts then you can install your own supercharger, it is that easy, really.

You can go the the TRD

website and download the installation instructions and read them

over to see what you are getting yourself into. I suggest if

you can, install the supercharger yourself. That way you will

be more familiar with the supercharger, hose connections and other

parts of the engine that can help you trouble shoot problems in the

future. From the countless emails I get, I would have to say

that most of the problems come out of installation errors from

dealer installations. There is also a good chance that the guy

at the dealer that is installing your supercharger is installing his

first one. If you do go that route try to find a dealer and a

mechanic at the dealer that has installed a few before yours and can

demonstrate to you that he knows what he is doing.

The most common installation

errors are miss routing vacuum lines, specifically the power

steering idle up line and the 4x4 vacuum supply line so pay specific

attention to those. The next most common error is not properly

installing the throttle body gasket. Putting it in backwards

will cause a check engine light in a short period of time showing a

lean code. Make sure you use the gasket that comes in the kit

and make sure it is in the right way. Lastly, it seems that

many dealers forget to install the check valve in the air assist

line. This prevents boost pressure from back flowing through

the air passages in the fuel injector tip and back out toward the

throttle body. This can take needed fuel with it preventing it

from being injected into the engine under boost. Make real

sure that the check valve is installed in the air assist line and in

the proper direction.

Back

to page index

Warranty:

Many people seem to get

confused about the warranty. Here is my impression of the

warranty, it is simple really. If you install the supercharger

it will be covered by a 12 month unlimited mileage warranty.

If you decide to pay the dealer to install it, the supercharger is

rolled into the remainder of the drive-train warranty. If it

is installed on a new truck by the dealer it will be covered for 5

years or 60,000 miles. I know that sounds good, but most of

the problems with installation seem to be from dealer installations,

go figure.

My truck had 44,000 miles on

it when I bought my supercharger and was putting about 30,000 miles

on it at the time. It seemed that if I paid the dealer to

install it I would be out of warranty in about six months. Of

course I installed it myself in less then four hours with a lunch

break.

The warranty on the truck

itself is not affected at all no matter who installs the

supercharger so do not worry about that.

Back

to page index

Where is the boost port?:

This seems to stump a great

many people including the pros at the dealer. The boost port

is the connection for things you may want to install with the

supercharger that need to have access to positive boost pressure

from the supercharger. These things may include a boost gauge

and other gadgets that need a boost pressure signal.

In the picture

above, the hose labeled as boost line 1 is connected to the boost

port on this 1st Generation TRD Supercharger. This is the

fitting that you want to connect thing like the boost gauge to so

that they will have access to boost pressure. The port labeled

as Boost Port 2 is also a port that will provide access to boost

pressure, but it is normally connected to the bypass valve actuator

and should be left alone.

This is a

picture of the rear side of the 2nd Generation TRD

Supercharger. This side normally faces the firewall. As

you can see the boost port comes plugged and is the ONLY port on the

supercharger that you can get a boost signal from. You will

have to remove this plug and screw in a nipple that you can attach a

vacuum line to. Many people opt to have the TRD boost gauge

installed when they supercharger is installed by the dealer and it

seems that many of them only read vacuum on the gauge. The

reason for this is that it is not connected to the boost port.

The gauge will not read properly if it is not connected to this

port. The port on the right labeled as vacuum port is the best

place to connect the 4x4 vacuum supply line to, another typical

error in the installation of the supercharger.

Back

to page index

Problems with the

supercharger its self:

Overall the superchargers

have proven to be very reliable and problems with the supercharger

itself have been very few. There have been some installation

errors, but that is expected to some degree.

I have heard of a few diaphragms

blowing out in the bypass valve actuators. On the later

version the vacuum line is connected to a vacuum source only to help

reduce this problem. I have installed a couple 2nd generation

superchargers and found that the bypass valve travel stop set screws were

not properly set by TRD and that caused the valves to over travel

and stick. You may want to check the adjustment on yours.

There have been some

superchargers with bad input shaft seals. This allowed the oil

in the nose drive to leak out around the pulley. The ones

under warranty had the entire supercharger replaced by TRD. If

this happens to you out of warranty you can just replace the nose

drive. You can get an exchange unit from Magnuson. This

problem seemed to affect a small batch of superchargers and other

then that has not been a big problem on units outside this one

batch.

If you are having oil

leaking out of your nose drive do not let TRD tell you it is normal

or it is just the break in lube. That seems to be their standard response,

the fact is it is NOT normal and needs to be address right

away. There are only four ounces of oil in the nose drive and

it can run dry very fast.

The supercharger does make

noise, it is supposed to. Under boost it will make a wonderful

whine sound that most find very pleasant. At idle it will make

a rattling like sound. That is from gear slack in the nose

drive. The supercharger uses straight cut gears in the nose

drive and at idle there is no load on the gears that they tend to

rattle back and forth a bit and that presents as a rattling

sound. It should go away if the engine is rev-ed up just above

idle. This is all very normal. As the supercharger ages

the rattle sound at idle may get louder. I replaced my nose

drive at 65,000 miles and the rattling sound was greatly reduced.

You can jump over to my supercharger

maintenance page for information on how to keep your

supercharger in top condition.

Back

to page index

Short

comings with the TRD Supercharger kit:

Although the Magnuson did a

fantastic job developing the supercharger for TRD, I feel there are

some short comings in the kit. The hardware part is beautifully

done, but there are some issues that have not been properly address

in my opinion. They are:

You can click on the links

above to find out why I think they are problems and what I have done

to fix the problems. Many of the other aftermarket

supercharger kits are complete kits and include different ways to

address issues with the ignition system, fuel system, and some even

include transmission upgrades to prevent damage from the added

power. Some of the folks that make a complete kit are Kenne

Bell, Stillen, Safari from Australia, and Alpine from South

Africa. TRD simply tells you that additional upgrades

are not needed. I disagree with that, but I guess because you

can bolt on the supercharger and it will run without any other

upgrades then I guess they are not lying, but I can tell you things

can be so much better with a few other add-ons.

Alpine from South Africa

makes a real nice supercharger kit for the Toyota 2.4 and 2.7 truck

engines. The kit comes complete with extra fuel injectors and

a piggy back engine computer to retune the engine for the

supercharger. TRD recently struck a deal with Alpine to

produce a stripped down kit for TRD to market as their own

kit. It uses a smaller supercharger and does not have the

extra injectors or piggy back computer and costs a lot more, but

does have the pretty TRD label on it. I think you would be

better served by getting the original Alpine supercharger kit that

is available in sever versions and boost levels. Because of

the import agreement between TRD and Alpine, TRD now has the

exclusive import rights to the 2.4 and 2.7 supercharger kits in the

US. There is a small loop hole that you may want to take

advantage of. It was several members or Tacoma Territory that

initiated the importation of the supercharger kit to the US that

later led to TRD marketing it. If you are a member of Tacoma

Territory you can still import the original complete kit direct from

Alpine. Look up the New England chapter site of Tacoma

Territory for more info on the 2.4 and 2.7 supercharger kit if you

want.

There is a good reason why

TRD does not include fuel and ignition upgrades with their

supercharger kit. I was told by the folks at TRD the reason

they do not do so is that they are being restricted by Toyota.

TRD is part of Toyota in North America and because they are an arm

of the manufacturer they would have to submit the entire kit with

upgrades for EPA approval just like it was a new complete car.

There simply is not enough profit in the supercharger kits to cover

the cost of getting something like this through the EPA approval

process, so can not include ignition and fuel system upgrades and

the engine will run without them, but I can tell you for certain, it

will run so much better with some additional tweaking in the fuel

and ignition system. That is my understanding of what I was

told by the folks at TRD.

When I was told that story

by a guy at TRD, I recommended a way for them to get around all of

those restrictions. My idea was to start another company

separate from TRD and Toyota, or have another company provide the

fuel and ignition upgrades for them. Then market the

superchargers at a much lower boost level where the stock engine

control system can handle things just fine and call that a stage I

kit with full warranty even if it needs to be 2-3 PSI. Then

tell people that want more that they can get the stage II kit from

the other partner company complete with a higher boost pulley and

fuel system enhancements with a disclaimer that they can not

warranty the upgraded kit. That will give every one what they

really want. Shortly after that conversation the Kazuma off

shoot of TRD was announced. When the Camry supercharger was

announced on the TRD web site they said that it came with a low

boost pulley, but would sell you a smaller higher boost pulley that

would need fuel system mods. They would not sell it, but could

refer you to a company that will sell you fuel system upgrades.

Interesting, don't you think?

Back

to page index

|